Electra, a Boulder-based industrial startup, has raised $186 million in Series B funding to scale its breakthrough process for clean iron production—a critical step toward decarbonizing one of the world’s most polluting industries.

The round brings Electra’s total funding to $214 million and sets the stage for commercial-scale deployment.

The round was co-led by Capricorn Investment Group and Temasek Holdings, with participation from a powerhouse mix of new and returning investors spanning climate tech, mining, steel, and manufacturing.

A Who’s Who of Strategic Backers

Repeat investors such as Breakthrough Energy Ventures, Lowercarbon Capital, Earth Venture Capital, and Builders Vision are doubling down, while new strategic partners include Rio Tinto, BHP Ventures, Roy Hill, and top steelmakers Nucor and Yamato Kogyo. Materials leaders like Toyota Tsusho and Interfer Edelstahl Group also joined the round, giving Electra end-to-end visibility and integration across the iron supply chain.

“This is more than funding—it’s a sign that the industry is ready for clean iron, now,” said Sandeep Nijhawan, Electra’s CEO and co-founder.

The Clean Iron Breakthrough

Iron and steel production accounts for nearly 10% of global CO₂ emissions, largely due to coal-fueled blast furnaces. While many decarbonization efforts focus on carbon capture or hydrogen-based alternatives, the company takes a radically different path.

Its patented, modular electrochemical process produces 99% pure iron from low-grade ores—an abundant, previously overlooked feedstock. Powered entirely by intermittent renewable energy, Electra’s system enables distributed, clean production without relying on fossil fuels or high-grade inputs.

This innovation not only slashes emissions but also reshapes the economics of ironmaking, offering a cost-effective, scalable pathway to greener industrial supply chains.

“Electra’s approach is a paradigm shift from traditional ironmaking,” said Dipender Saluja, managing partner at Capricorn. “It’s exactly the kind of bold, systems-level innovation we back.”

From Lab to Market

With the new funding, the firm will break ground on a demonstration plant in Colorado later this year. The facility will produce sample volumes of clean iron for testing and qualification by partners, paving the way for a commercial-scale facility expected before 2030.

This phase is about more than proving the tech—it’s about building confidence in real-world performance, reliability, and supply chain integration.

“Customers want clean iron, but they need to trust it works at scale,” said Nijhawan. “That’s exactly what we’re delivering.”

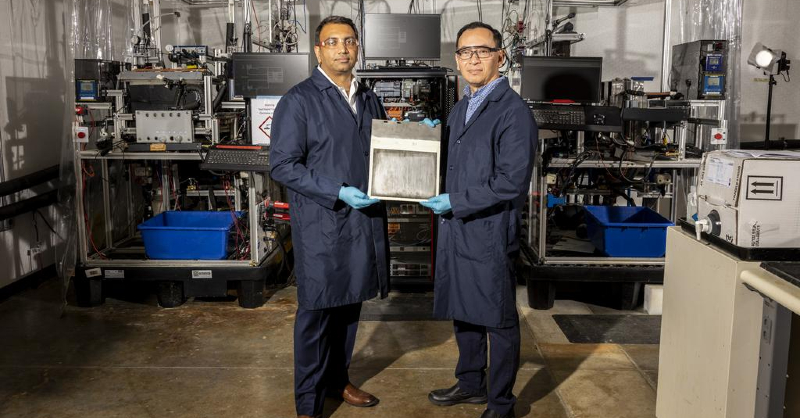

A Founding Mission: Reinvent Industry

Founded in 2017 by Sandeep Nijhawan and Quoc Pham, the industrial startup brings together deep expertise in materials science, engineering, and commercial scaling. The company’s goal is simple but ambitious: reinvent ironmaking to serve the planet without compromising industrial performance.

Electra’s team has moved quickly from idea to implementation, and its growing commercial pipeline reflects a surging demand for low-carbon materials—especially in sectors like automotive, infrastructure, and construction.

Why Now?

The timing couldn’t be better. As global automakers ramp up use of electric arc furnace (EAF) steel to cut embedded carbon, the need for sustainable iron feedstocks is soaring.

“Technologies like Electra’s are critical to our ability to meet growing demand for low-carbon EAF steel,” said Noah Hanners, EVP of sheet products at Nucor. “As we transition to greener steel for the automotive industry, sustainable inputs like Electra’s clean iron will become essential.”

Electra is proving that the heavy industries powering the modern world don’t have to be heavy polluters. With a transformative new process, top-tier backing, and a clear path to scale, the company is forging a cleaner future for iron—and the industries that rely on it.