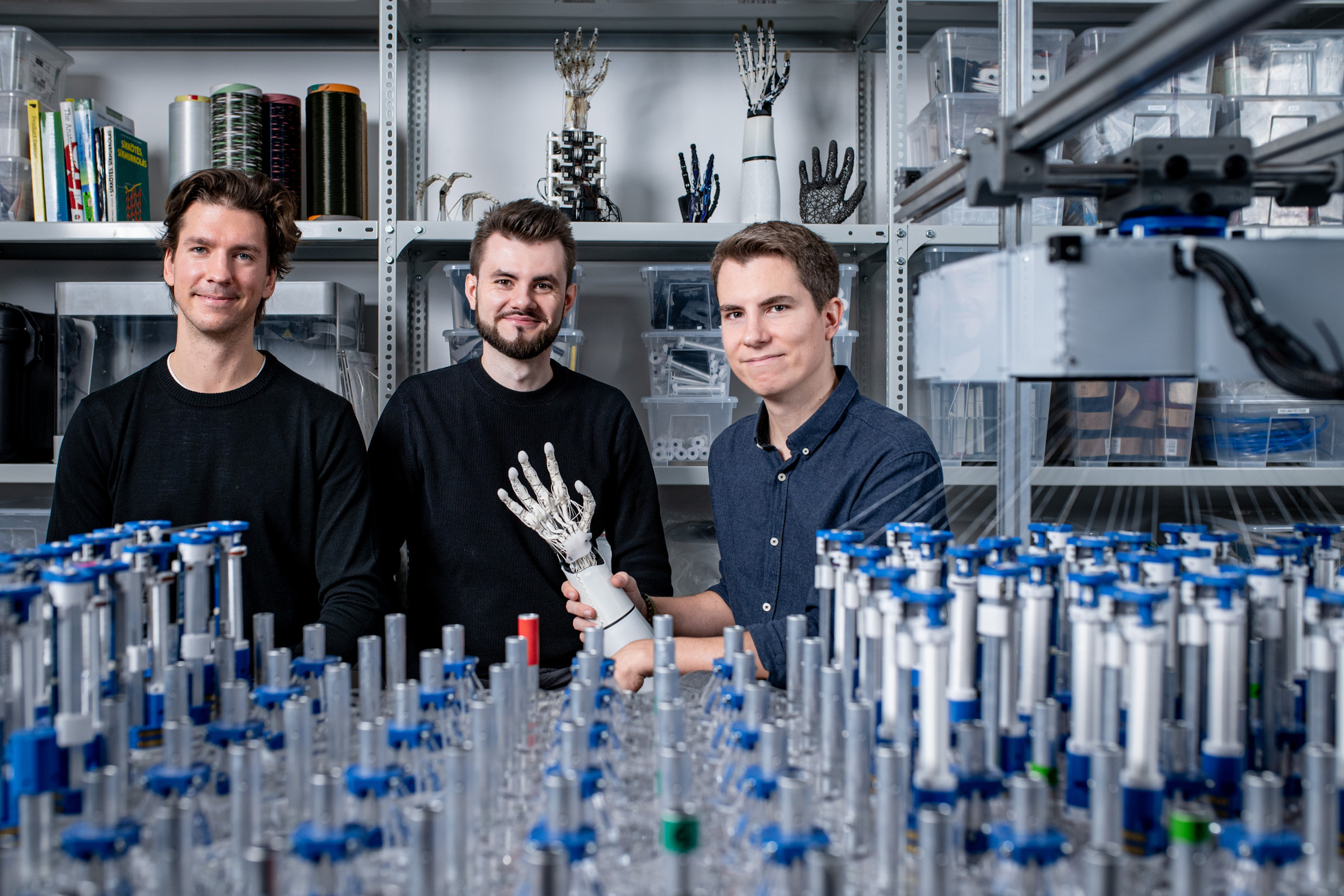

Hungary-founded robotics manufacturing startup Allonic has raised $7.2 million in pre-seed funding to industrialise a new approach to building advanced robotic hardware.

The round was led by Visionaries Club, with participation from Day One Capital, Prototype Capital, SDAC Ventures and TinyVC. The financing marks the largest pre-seed round completed in Hungary to date.

Headquartered in Budapest with a joint US base, Allonic is focused on addressing what it sees as robotics’ most pressing constraint: manufacturing.

Moving beyond manual robotic assembly

While advances in AI have significantly improved robotic perception and autonomy, the physical construction of robots has remained largely unchanged. Many sophisticated systems are still assembled manually from hundreds of precision components, making them expensive, difficult to customise, and hard to scale.

As robots become more complex and are expected to operate safely alongside humans, the limitations of traditional manufacturing processes have become increasingly apparent.

Allonic is tackling this issue at the infrastructure level with a proprietary production method called 3D Tissue Braiding. Instead of assembling discrete parts such as bearings, screws, and joints, the company weaves robotic “tissues” directly over a skeletal structure in a continuous, automated process.

Inspired by the structural strength of rope, the approach integrates tendons, joints, and load-bearing elements into a unified form. For example, a robotic finger can be created from a minimal number of rigid core components reinforced by hundreds of fine fibres that anchor into the structure, mimicking biological connective tissue. This reduces mechanical failure points and eliminates bulky fixtures.

According to the company, this method enables the production of robotic bodies that are both strong and compliant, while significantly simplifying manufacturing.

From digital design to finished hardware

Allonic’s platform combines custom hardware and software that translates high-level robotic designs directly into production instructions, similar to how slicing software prepares files for 3D printing.

Multiple materials can be embedded during production, including elastics, wiring, and sensing components. This allows complete robotic limbs or components to be manufactured directly from digital designs without complex supply chains or distributed assembly.

By consolidating mechanical complexity into an automated process, Allonic aims to reduce both the cost and expertise required to build advanced robotic systems. What previously required weeks of engineering and high capital expenditure can, according to the company, now be produced in minutes at significantly lower cost.

This model enables rapid iteration, on-demand production, and easier replacement of robotic manipulators. In industrial environments, components could be swapped quickly, reducing downtime and making custom hardware economically viable at scale.

Early traction and industry interest

Since unveiling its technology in May 2025, Allonic has completed its first pilot in electronics manufacturing, targeting tasks that require greater dexterity than traditional industrial robots can provide.

The company reports growing interest from humanoid robotics developers and major US-based consumer technology firms, reflecting broader industry recognition that hardware scalability remains a key barrier to the next phase of robotics growth.

Benedek Tasi, Co-Founder and CEO of Allonic, said that while much attention is focused on software and intelligence, hardware constraints still limit what robots can achieve.

He noted that long-standing trade-offs between durability, softness, strength, and dexterity have been shaped by manufacturing limitations, and that removing these constraints could unlock entirely new robotic capabilities.

Building infrastructure for the robotics era

Allonic has assembled a team of 15 engineers across robotics, materials science, and computational software. The company plans to use the newly raised capital to further develop its 3D Tissue Braiding platform, expand its engineering and operations teams, and support additional pilots and early commercial deployments with industrial partners.

Investors say the disconnect between rapidly advancing AI software and slow, costly hardware production has become a structural bottleneck for the robotics industry. By rethinking robotic manufacturing from the ground up, Allonic aims to position itself as foundational infrastructure for the next generation of robotic systems.